Lets face it – the majority of the cost of a tent is for the fabric. So what should you look for?? We only use cotton canvas to make our tents. Why cotton? Its natural ability to breathe. That is the reason most clothing is made from cotton – it’s comfortable to be inside. What separates us from the lower quality tents (often but not always imported) is the TREATMENTS applied to the canvas. The Sunforger ® treatment is applied to our canvas in Butler GA. It retains the canvas natural ability to breathe and has minimal harmful effects on the canvas itself. Yes, its the TREATMENTS that play a huge role in how the canvas performs over the life of the tent.

Under normal circumstances a Sunforger® treated tent with proper care will easily last our average user a lifetime. If you purchase a tent that is not treated with the Sunforger® treatment – “please keep us in mind for your next tent purchase”.

Why our canvas is better?

For almost 60 years, the Davis family has been making tents in Colorado. Through these decades the three critical factors that go into making the highest quality tents have remained constant, they are:

- 100% cotton is the preferred canvas for tents – WHY 100% COTTON? Breathability! The reason breathability is so important is to minimize and eliminate condensation. Just 4 people in a tent produce 2 liters of condensation from their breath in one night! Add to that other elements that put moisture into the air – boiling water, heating with propane, drying your clothing, etc. – and you create a wet interior. Properly treated cotton allows this moisture to escape through the tent, keeping you warm and dry.

- Canvas treatments have become a critical factor differentiating a high quality from a lesser quality tent. SunforgerR has been the leader in the fabric treatment industry for more than 50 years because of its ability to retain the canvas’ natural ability to breathe without contributing to the fabric’s disintegration. – WHY SUNFORGERR TREATED COTTON? Breathability, Longevity!

The type of treatment used to make your tent resist the effects of ultra-violet (UV) light from the sun, repel water and mildew, or retard the spread of fire is a critical factor not only for its impact on breathability, but also on how long your tent will hold up.

If you tore a single piece of untreated canvas in half and then applied Sunforger to one-half and a different treatment to the other, the Suforger treated half would perform best in terms of strength, ability to breathe, overall integrity, and longevity. Some would have you believe that all treatments are equal or a matter of brand preference (like CokeR or PepsiR): this is simply not true. Inferior treatments impede breathability and cause more rapid deterioration of the canvas when exposed to the elements, making the tent both less comfortable and reducing its usable life. For these reasons, we pay extra for the Sunforger treatment!

As one of the larger tent manufactures we get approached by many importers (each and every week) wanting us to add their tent to our line , while we briefly considered offering an “economy line” of foreign-produced (and, therefore, not Sunforger treated) tents, we have not yet found one that we felt comfortable putting our reputation on the line for. It will be interesting to see reviews on these imported tents after a few more years goes by.

Canvas construction – including number of threads per square inch and tightness of weave – is important in determining the ability of the fabric to keep heat in and rain out.

Our 10 oz. double fill, cotton army duck has a proven track record in making tents that provide an optimal hunting experience not just at the time of purchase, but over many years. This material has an excellent strength to weight ratio and has proven itself the superior fabric for making tents. One of the first questions we get when speaking with a potential customer is “what does that tent weigh”? The 10.10 oz canvas we use is the “sweet spot” for being lightweight yet durable. We can make tents from heavier canvas upon request, but in most cases there is no benefit to the end user. – here are a couple of pictures of different 100% cotton canvas

This visual inspection will eliminate some but not all “imposters” – materials that can look like top quality to the naked eye, but are still inferior because of “combing.” Combing cotton is the process by which raw fibers are sorted by length. In top quality canvas (like the canvas we use), the long (most desirable) fibers are spun into individual threads, two of which are twisted together to form plied yarns we refer to as “double fill.”

Inferior quality canvas is made up of short fibers spun together. While not visible to the naked eye, the difference is measured by two processes: tear strength tests and burst tests. The industry measures canvas strength with high tech equipment to assess how much stress a fabric can endure before it fails. Tests are done in both directions of the weave (weft and warp) as well as of the product as a whole. In the “burst test” a ball is pushed through the fabric to determine at what point a hole will occur. Our canvas – LONG FIBER, double fill cotton has about double the tear and burst strength as a short fiber (usually imported) product. So why don’t all tent manufacturers use this superior, long fiber, double fill cotton? In a word: cost. The lower grade canvas is cheaper.

We’re good at building a website (just notice how much of our information has been plagiarized on other sites), but we are great at making tents. Our knowledge, expertise in this industry, and our combined experience have refined our products to what we make today and what we will stand behind for years to come!

We control all facets of our tents’ production from our factory in Denver, unlike many other companies that merely sell imported tents. There is a reason for every patch and reinforcement on our product, just as there are reasons for what we do not do. If you see something on another company’s tent that you feel you would like, we would be happy to incorporate that feature into the tent we make for you, or explain why we don’t recommend it.

As our dad, Art Davis, was fond of saying, “You can make a good tent in the same amount of time it takes to make a bad one.” To us, the choice is obvious.

_______________________________________________________________________________________________________________________________________________________________________________________

Below are a couple of our old outdated “canvas information pages” we left them on this page as there are a few points not covered in the condensed edition above.

12 years ago, I started this page as a service to our valued customers and it’s proven to be one of our most visited (and plagiarized!) pages. At that time, if your tent was made of “double fill” canvas, it meant quality. However, with the recent influx of imported canvas and foreign-made tents, this alone is not enough anymore. Inferior materials are now being labeled double fill in an attempt to pass them off as the same quality as ours. They are not. So, before you spend $400-$1000 on a tent, you need to know how to determine the difference between high and low quality canvas.

A good idea when comparing manufacturers is to request a swatch (sample) of the fabric. Some vendors will not be able to do this as they only sell, but do not manufacture, the tents. The first thing to note is the number of brown spots. These comes from the quality of the cotton used in the manufacture of the material. First run fabric (as shown on the left) is made from the center part of the cotton bulb and contains the purest cotton. Once that portion of cotton is harvested, the dregs are used to make the second rate material on the right. This includes more pieces of the outer husk of the cotton flower which show up as spots in the finished product. This creates a fabric termed “tarp grade” which has less strength and is more prone to leakage and mildew. So doing a visual inspection is your first – but not only – step in determining a quality canvas. Because of different issues, some inferior materials can look like top quality ones to the naked eye.

There is a process of “combing” cotton in which the raw fibers are sorted by length. The long strands are the most desirable and are spun into individual threads, two of which are twisted together to form plied yarns we refer to as “double fill.”

But all double fills are not created equal!

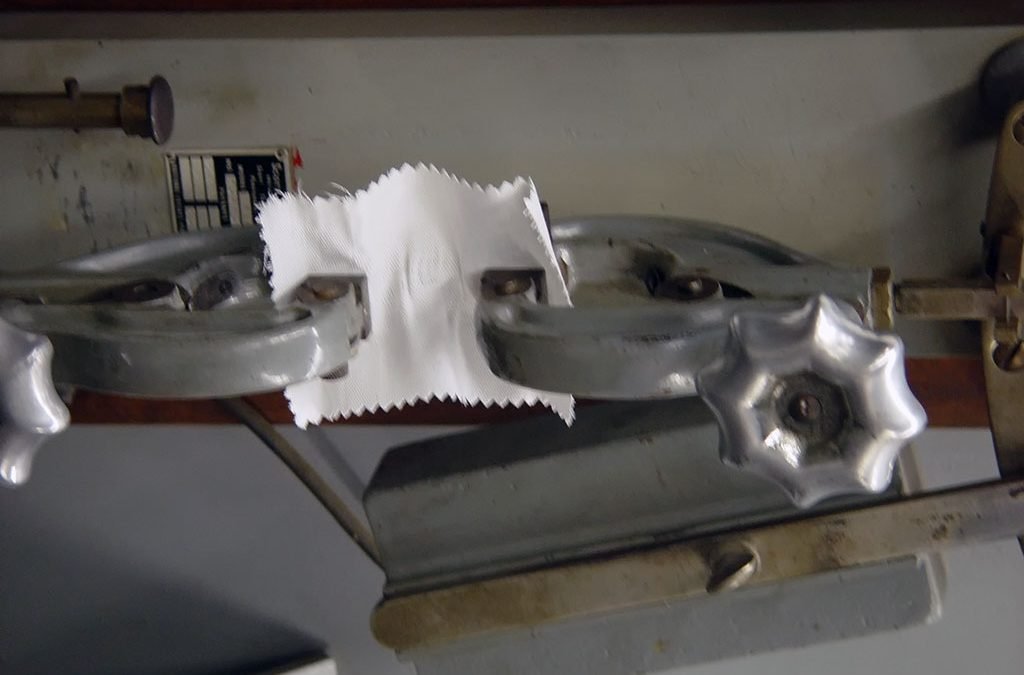

While top quality canvas is made up of long fibers spun into yarn, inferior quality canvas is made up of short fibers spun together. While not visible to the naked eye, the difference is measured by two processes: tear strength tests and burst .The industry measures canvas strength with high tech equipment (see photo’s), assessing how much stress a fabric can endure before it fails.

Tests are done in both directions of the weave (weft and warp) as well as of the product as a whole (Called a burst test — in which a ball is pushed through the fabric to determine at what point the fabric bursts, or a occurs). Our canvas (long fiber, double fill cotton) has about double the tear and burst strength as a short fiber (usually imported) product.

Here’s our much requested, often copied original canvas information page…

Buzz words in the industry are 10 ounce, 12 ounce, 14.90, numbered duck, single fill, double fill, army duck, bull denim, twill, shelter duck, untreated, both wet and dry finishes of canvas, water and mildew treated, water mildew and fire treated, sunforger, boatshrunk, marine grade… It can all be overwhelming! And that’s just for canvas!

Then there are other materials like: realite, polaris, gala, nylon… all the synthetic fabrics that DO NOT BREATHE! That’s the reason we don’t use them for our tents. I read somewhere recently that with cool, dry conditions the human

body will produce 1/2 a liter of condensation from their breath in one night! Add this to three buddies and you have 2 liters of moisture dripping from the roof of your tent because the moisture cannot escape from those fabrics.

Having said that, let me share with you what we do know about canvas in plain English. How do you choose the canvas that is right for you? The short answer is 10.10 oz. marine grade canvas. Here’s why:

One of the biggest mistakes I have seen people make when purchasing a canvas wall tent is assuming that “heavier is better,” that a 12 oz.. canvas wall tent must be better than a 10 oz.. canvas wall tent or that the 14.90 canvas must make a better tent than either of the above. Just because it is heavier, people assume that it will be more durable and will outlast and out perform a lighter canvas. WRONG – this is simply not so because of “fill.”

The reason the 10 oz.. fabric that we use to make our canvas wall tents is superior

to the above mentioned fabrics is due to one VERY important feature: our 10 oz. cotton is known as DOUBLE FILL – where two threads are twisted together to make a single stronger, more durable thread. What that means to you is that the fabric is a much tighter weave because the threads are much closer together – more “filled in.” I like to compare it to buying a bed sheet or fine linen. Quality in fine linen is rated by threads per inch not by how heavy it is. It is the same with cotton (canvas); it is much more important to consider threads per inch and hence the tightness of the weave. Let’s think about that for a minute…let’s think about canvas as a filter and what we are filtering is water. Do you want a fabric that has course threads and is heavy? Why? Or one that is tightly woven with a lot more threads per inch? It makes sense that a tighter woven fabric (filter) will keep more moisture out of a tent and more heat in. As for the durability, the double fill adds to the integrity of the fabric which gives it far better durability than the single fill products.

Army Duck, Army Duck, Army Duck… What is this and do I want it? Yes and No. “Army Duck” merely refers to a military designation — the material must be of equal strength in both directions (warp and fill), it does not address the quality of the fabric. So you can have desirable or undesirable army duck. It still boils down to threads per inch and treatments which will tell you good army duck or not so good army duck.

I’m sure you see why double-fill cotton makes a better wall tent – it breathes and is of superior quality.

The next area of confusion is what kind of fabric treatment do you need? This is tough because it depends on you the end user,

Lets say we set up three 14 x 16 wall tents all 10 oz. double fill:

#1 The first tent is untreated meaning no treatments for water repellency or mildew.

#2 The second tent is water and mildew treated (sunforger / marine grade / boatshunk).

#3 The third tent is water, mildew, and fire treated.

Then…….It rains, snows, hails, and the wind blows…ALL THREE TENTS WILL PERFORM GREAT! So what’s the difference?? The difference is how you treat them when you are done with your trip

Tent #1 . If you roll this tent up when it is wet and let it set for three or four days you might as well throw it away because it will be ruined. It has mildew! You need to be absolutely sure an untreated tent is bone dry when you store it for any length of time. We have customers who have had these last 30 years and are still using them. We have also had customers ruin their tent the first time out. (Note you will also have some shrinkage.)

Tent #2 (Our recommendation) Some call it sunforger, others boatshrunk or marine grade. What that designates it has been run through the vat twice and factory treated for water and mildew repellency, The big advantage here is the mildew repellency; even though you want to avoid storing your tent wet, one that is water and mildew treated is much more forgiving if you are a bit careless.

Tent #3 is the same as tent #2 but with an additive to prevent the spread of fire. To burn this tent, it would take “supported flame” – i.e. if you held a flame directly to the tent, it would burn, but if you removed the flame source the tent would stop burning. Tents #1 and #2 could continue to burn without the flame source. Please note that CA, LA, MA, MI, MN, NY, and NJ are states that require any tent shipped to their state, or set up within their state needs to meet the cpai-84 fire retardant code.

Beware! Not all 10.10 oz. fabric and treatments are equal. Before you buy any tent make sure you are buying sunforger finished canvas. Not some cheap imported knock off. You will be glad you did.